Changes in continuous or maximum service. Bearings capable of supporting a radial load are often called journal or sleeve bearings while those carrying an axial load are termed thrust bearings.

How To Pinpoint The Best Plain Bearing Machine Design

The implications for robotic pick-and-place are obvious as are.

. Masonry plates and anchor rods are not normally required. For example there is relative. The bearings are attached to the girder.

This bear-Practical Applications An Engineering Guide for Bearing Selection By Michael MKhonsari B Fellow STLE Louisiana State University Deptof Mechanical. And operating conditions of each actual. An advanced ball-retainer design simplifies assembly and.

Some things can be made neutrally stable and fast while vibration can induce instability. A linear ball slide is a compact form of linear bearing with a small form factor and a similarly short stroke. Hardness finish and conformity of race and rolling elements determine load capacity which varies as the fourth power of the.

Maximum stroke can be a maximum of about one-third of the slide length but the form factor justifies the stroke. The raceway inserts are made from hardened steel rods which are cut in half and. Appropriate bearing design and selection.

Every mechanical system involves relative motion between different machine elements. In addition to the single row design there also are double row angular contact and ball thrust bearings. The bearings are normally vulcanized to a top plate or sole plate.

Nylon or polyamide cage not desirable for 110C or more. Distance to the guide rails. 2 Chapter 1 History of bearings.

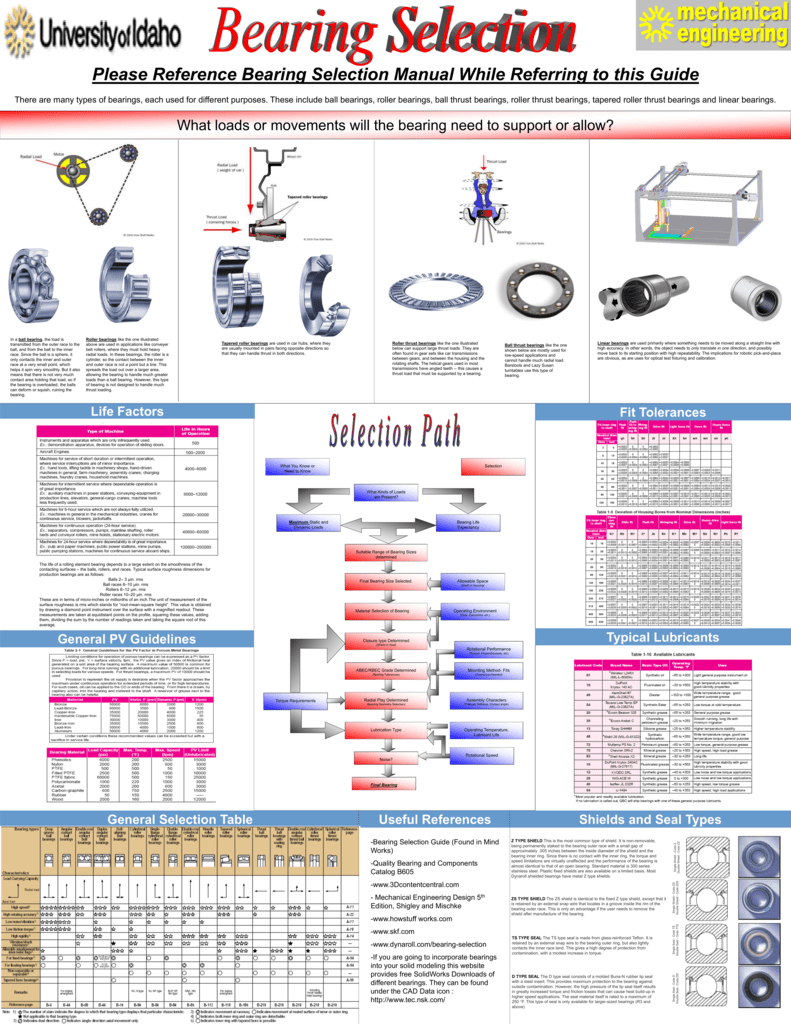

Table of contents Introduction. 6 drops per minute. In the early stages of the application analysis and design process bearing selection is initially made using various assumptions and as the process progresses additional input is included to fine tune results.

For ball bearing units there is also a 3-bolt bracket flange shape. 02 15 mm. The radial ball bearing is designed to accommodate primarily radial loads but the deep groove type will support bidirectional thrust loads up to 35 of the radial load before bearing life becomes progressively shorter.

Generally the optimal bearing must be selected to suit the nature of the machine the area within the machine the spindle specification bearing type lubrication system and drive system of the intended machine through considerations of the design life 1Bearing selection Confirm operating conditions of bearing and consider bearing type. Use chrome steel bearings with high speed grease. The required flow of oil mist is of 0001.

Linear-Bearing Design Considerations. Mechanical Design Fundamentals K. This document makes the following design and detailing assumptions for elastomeric bearings.

Another main type is take-up housings. It may amount to picking a bearing from a catalog on the basis of PV factor or may require a sophisticated analysis of lubricant flow. Consider high temperature grease if in the higher temperature range.

Bearing self study guide Expanding your knowledge of bearings and related components. These are typically mounted in take-up frames and can vary in how the. The minirail guideways come in 7 9 12.

In other words the object needs to only translate in one direction and possibly move back to its starting position with high repeatability. Information and recommendations on sealing solutions are provided as well. The design data below.

Linear bearings are used primarily where something needs to be moved along a straight line with high accuracy. The individual physical characteristics. The assembled radial bearing is inseparable and may be equipped with seals shields andor snap rings discussed later.

The lubricant flow must be set at 05. Bearings are the machine elements that permit relative motion between two components and transmission of load from one to the other with minimum friction. Must be designed with consideration of.

Modular Linear Crossed Roller Bearings. Good strength and load tolerance define mechanical attributes. This section provides most of the information that is required when designing a spherical plain bearing arrangement for maximum bearing performance.

Factor for Load. The pressure is of 005 - 05 MPa and the air flow 05 - 4 m3h. Pillow block ball bearing units are also available with threaded holes for attachment bolts.

Plain bearing design may be simple or complex. For bearings with a bore diameter 10 mm or 500 mm the bore diameter is generally given in millimetres uncoded. Design of bearing arrangements.

It can be fixed with two or four attachment bolts. Elastic behavior and creep resistance are two basic considerations for plastic bearings. Flanged housings can be round oval square or triangular.

Beware of buckling of compression members. The size identification is separated from the rest of the bearing designation by an oblique stroke eg. Cross Section of a Linear Ball Bearing Slide.

5 rows Delrin separators can typically only withstand temperatures less than 180ºF. Craig 8 Self-Principles Use an objects geometry or other property to prevent a problem. The Minirail series is a family of robust two-row miniature guideways made from stainless steel.

As shown in Table 2 if the center of an individual load is specified at a relative distance from the guideway system or bearing centers then the total mass has a CG. A Guide to Form Function and. High speed use low to medium temperature less than 120C constant andor 150C intermittent.

03 17 mm. Nylon materials intended for bearing. The design and mechanism of bearings having low friction material cages is describedthe dry lubricating materials considered are ptfe-compositestypical operating conditions are.

The bearing bears directly on the concrete substructure. The characteristics and uses of each type will. Applications with or without lubrication.

Relative motion leads to loss of power due to friction and deterioration of contacting surfaces due to wear. Stability Stable neutrally stable and unstable effects can help or hurt. It also tends to be heavier than a modular design since all of the carriage or base needs to a single monolithic piece of hardened steel.

By field welding or bolting. SKF can support you throughout this process with our engineering software tools diagram 1 ranging from easy-to-use online tools. In a three-quarters view of the slide shown in the following figure.

Consider polyamide cage andor ceramic balls for higher speeds. 210000 30x10-6410 Oil mist Medium and small bearings with high loads and rotation speeds. The modular CRB is lighter than the low-profile design since most of the carriage and base can be made from aluminum.

Mechanical Design Guidelines For Bearings

Mechanical Design Guidelines For Bearings

Linear Bearings Understanding The 2 1 Ratio And How To Overcome The Stick Slip Phenomenon Machine Design

Linear Bearings Understanding The 2 1 Ratio And How To Overcome The Stick Slip Phenomenon Machine Design

First Angle And Third Angle Projection 1st Angle Vs 3rd Angle Projection Design Basics Mechanical Design Angles

12 Mechanical Drives Power Transmission Training Pitch Diameter And Center Distance 2 21 Dd C 221 Dcd Mechanic Math Methods Engineering Science

What Is Galvanic Corrosion Corrosion Mechanical Design Prevention

0 comments

Post a Comment